Our Businesses Coating

Our

Business

Precision Coating

Precision Coating

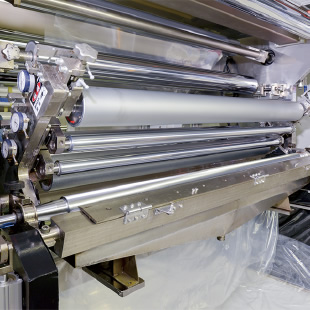

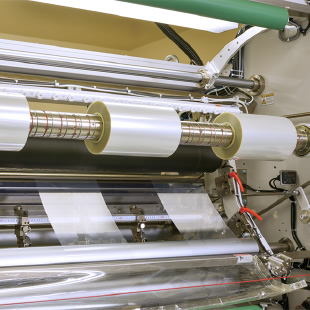

Our precision coating division handles coating commissions for glue, adhesive, and functional paint coating for a wide variety of applications (smartphones, semi-conductors, storage media, building materials, etc.) using machines equipped with coating heads with a cleanliness class of 1,000 or less.

Along with IS09001 certification, we have established a system that enables us to meet customers' diverse needs with a robust management structure that emphasizes objectivity and confidentiality.

Along with IS09001 certification, we have established a system that enables us to meet customers' diverse needs with a robust management structure that emphasizes objectivity and confidentiality.

Clean room

Clean room Rotogravure head

Rotogravure head Comma coater head

Comma coater head Lip coater head

Lip coater head Slitting machine

Slitting machine

Overview of Coating Machinery Specifications

| 1. Base material width | 400–1,570 mm |

|---|---|

| 2. Base material thickness | 4.5–600 µm |

| 3. Base material type | Various types of film (PET, PEN, TAC, PS, PP, PE, PI, etc.), metallized/spatter roll, copper foil, aluminum foil |

| 4. Coating heads | Comma coater, lip coater, compact gravure coater, gravure direct/reverse coater |

| 5. Coating thickness (dry) | Nano level–250 µm |

| 6. Dryer specifications | 70–180°C, kiln length: 9–20 m, roll support, floating |

| 7. Line speed | 1–150 m/min |

| 8. Laminating equipment | May be heated to a maximum of 200°C |

| 9. Cleanliness (actual values) | Inside room: 2,000–3,000, coating heads: 1,000 or less, inside dryer: 100 or less |

| 10. Other | UV irradiation equipment, accumulator, in-line defect detection system, in-line foreign matter removal equipment, delamination device, in-line slitter |

Other Owned Facilities

| Slitting machine | Maximum width: 1,600 mm, in-line defect detection system |

|---|---|

| Blending chamber | |

| Aging room | 4 |

| Cold storage (5°C) | Set at 5°C |

| Various measurement devices | Spectrophotometer, tensile tester, thickness gauge, weighing machine, etc. |

| Other | Various coating fluid mixing devices, various coating fluid supply pumps, filtering equipment |

In addition to the above, prototype machines that may be adapted to a width of 200 to 700 mm are available. These may be used for pilot production, small-batch test coating, etc.

For details, please contact us by email.

Contact usProcessing Examples

| Commissioned products | Solvent-based adhesive coating, solvent-based glue coating, water-based glue coating, resin coating with filler, hard coating, polyimide coating, sensitive material coating, other functional resin coatings |

|---|---|

| Products developed in-house |

Collaboration with the packaging division is being pursued with a view to developing functional coatings. Functional packages are in development. Transparent UV cut film (soft packaging material, laminate material, shrink film), functional metallized film, molded film, other functional films |

Toin Corporation

Toin Corporation