Our Businesses Packaging Business

Our

Business

Packages

Packages

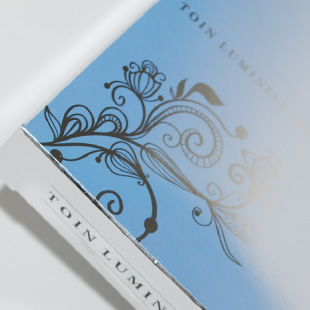

- Cosmetics

- Using specialized printing and processing technologies, we fabricate attractive cosmetics packages that highlight the value of products and enhance their in-store appeal.

- Pharmaceuticals

- Our pharmaceutical packages, whose users include healthcare organizations, are produced based on rigorous management of hygiene and standards.

- Food Products

- Our food product packages, made with high-quality offset printing and surface treatment to tailor consumers' needs, may be mass produced in accordance with customers' sales conditions and manufacturing lines.

- Daily Necessities

- Our packages suited to products in various formats may be mass produced in accordance with manufacturing lines thanks to our excellent technological capabilities.

Package Manufacturing Facilities

Offset printing press

Offset printing press Press coating machine

Press coating machine Silk printing machine

Silk printing machine Hot stamping press

Hot stamping press Die cutting and creasing machine

Die cutting and creasing machine Paper collator

Paper collator Automated packing machine

Automated packing machine Window labelling machine

Window labelling machine

(2-piece) Window labelling machine

Window labelling machine

(shrink film) Folder gluer

Folder gluer

Our

Business

Labels

Labels

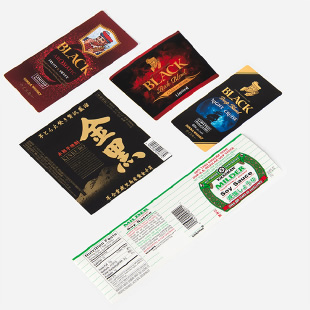

- Labels

- In order to meet a wide range of customer needs, we have equipment of various types with which we can produce pressure-sensitive labels, glue labels, delayed labels, POP labels, and more.

Tack labels

Tack labels Single-sheet labels

Single-sheet labels Delayed labels

Delayed labels Glue labels

Glue labels POP labels

POP labels

Label Production Facilities

Flexographic label

Flexographic label

printing machine Intermittent offset

Intermittent offset

printing machine Delayed-tack

Delayed-tack

adhesive coater Busch™ punching machine

Busch™ punching machine

Our

Business

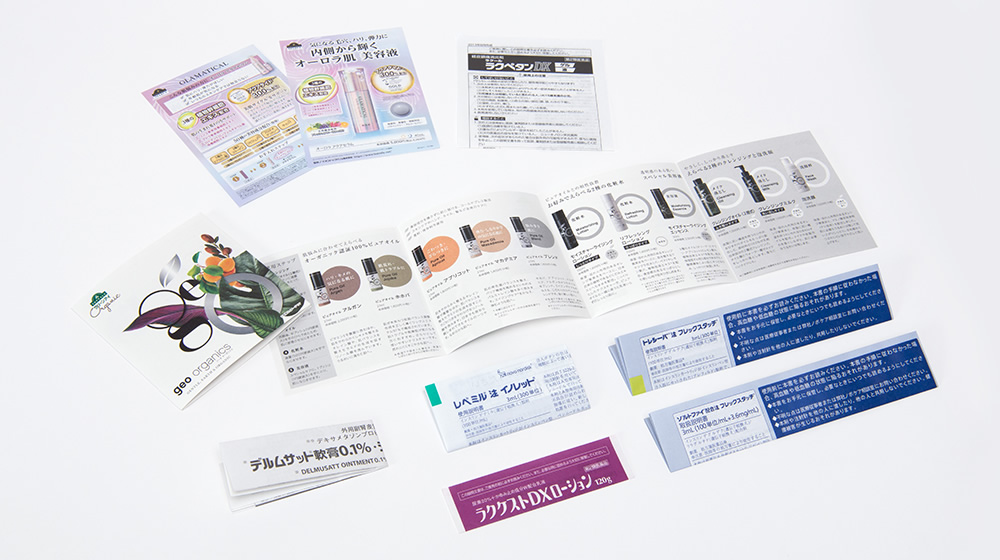

Instructions (Package Inserts)

Instructions (Package Inserts)

- Instructions (Package Inserts)

- From pharmaceuticals (medical/OTC use) to cosmetics, we produce instructions (package inserts) based on stringent quality standards that provide consumers with accurate product information.

Instruction (Package Insert) Production Equipment

Rotary press

Rotary press Offset printing press

Offset printing press Folding machine

Folding machine

Our

Business

Technologies

Technologies

Printing and Processing Technologies

-

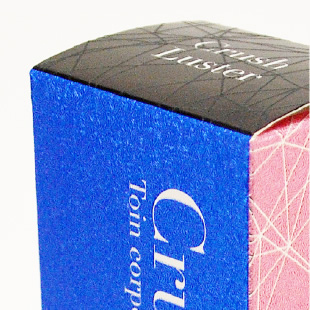

- Crush luster

- This printing technology applies three-dimensional textures that reflect light randomly.

-

- Hot stamping delayed labels

- These high-quality delayed labels may be embossed using specialized equipment.

-

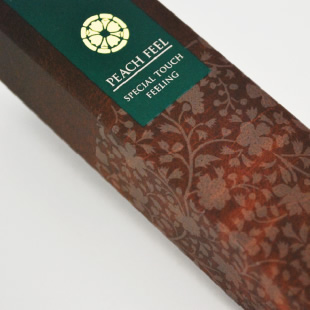

- Peach-feel coating

- A luxurious matte surface treatment with a satiny feel.

-

- Luminist ink

- A printing technique that creates a beautiful, aurora-like luster.

Structural Forms

-

- Shrink film

- An alternative to blister packaging, this environmentally friendly, resource-saving package makes it possible to highlight information while displaying the product.

-

- Tamper-proof

bottom-filled carton

(patent pending) - Since sets may be completed by inserting the product via the bottom of the box, the process from box assembly to sealing is streamlined.

- Tamper-proof

-

- Two-Piece Carton

- Created by combining paper with resin sheets, this package makes it possible to view the contents while reducing the amount of plastic used.

-

- Package with integrated insert

- Since the insert is printed directly on the package, it is not necessary to enclose it. This has the benefits of streamlining assembly work and saving resources.

Environmentally Friendly Materials

-

- FSC-Certified Paper

- (lineup includes both standard type and original Toin products)

- This certified paper is created with wood from forests cultivated in accordance with standards and guidelines for appropriately managed forests.

- Original Toin paper board

Brilliantly white and exceptionally smooth, this paper board is suitable for backside printing. - Original Toin metallized paper

Ivory paper is laminated with film at our own overseas plants.

- Original Toin paper board

-

- Bagasse paper

- (line-up includes both standard-type and original Toin products)

- This natural paper is made using environmentally friendly non-wood pulp (bagasse).

- Original Toin paper board

Enjoy the natural texture of this uncoated paper. FSC-certified. - Original Toin metallized paper

Original Toin paper board is laminated with film. FSC-certified.

- Original Toin paper board

-

- Recycled PET

- Eco-friendly PET sheet recycled from PET bottles collected in cities.

-

- Fine Pulp Mold

- Eco-friendly molded items made from recycled paper. It is possible to produce rigid products with smooth surfaces and complex shapes.

-

- LIMEX

- A substitute for paper and plastic whose main raw material is limestone.

-

- MAPKA

- A substitute for plastic whose main raw material is paper powder.

-

- Biomass ink

- This ink is partially made using renewable natural resources (biomass).

-

- Biodegradable labels

- These eco-friendly labels use biomass plastic that decomposes naturally as the surface substrate.

-

- Biodegradable film

- Thanks to the use of materials that decompose in water and carbon dioxide due to bacteria in soil, this film's environmental impact is reduced.

Other

-

- UV cut film

- This film cuts UV rays by 99%. Using it makes it possible to protect contents from UV rays.

-

- Anti-scratch film

- This is a hard-coated film that protects products against scratches. Scratches will disappear.

Our

Business

Design, Prepress, and Prototyping

Design, Prepress, and Prototyping

-

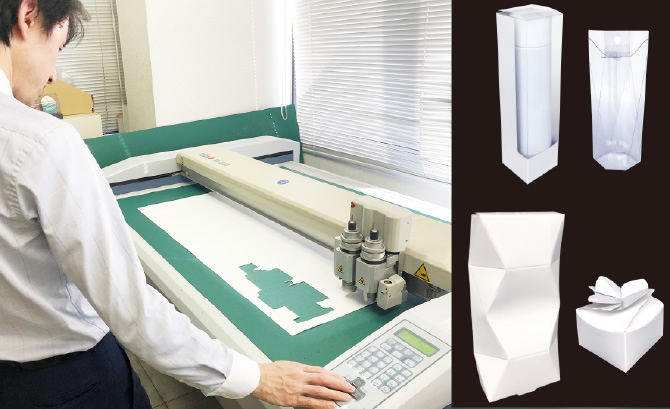

- 1. Structural Design

- Using CAD software, our structural designers plan and design paper articles, proposing unique and highly reliable forms to the customer. Once they have been adopted, we provide development diagram data for use in creating designs by the customer, adjust the design to improve productivity with factory production in mind, and offer other services. Since the department is equipped with cutting machines, it is possible to create plain samples with a high degree of precision.

-

- 2. Design

- Our designers carefully determine the customer's needs then propose graphic designs, structural forms, and printing processes suited to the product. Along with design sketches, they can make proposals based on package mock-ups that make it easy to visualize the actual finished item. For products focused on strategic design, we propose highly appealing designs that draw on eye tracking-based line-of-sight research and market surveys/analysis by marketing experts.

-

- 3. Prepress

- In order to respond rapidly to customer requests, we have created a plate-making system in which specialized staff with expert knowledge complete page makeup and image processing based on digital data using Apple computers. Data is managed with a high level of security on our dedicated plate-making servers.

-

- 4. Sample Creation

- For high-quality design requests for pharmaceutical packages, cosmetics packages with high added value, and the like, we create package samples to meet customers' requirements. Based on plate-making data, a comp that makes it possible to preview the printed finish is created using a DDCP (direct digital color proof). Since what is shown to the customer is therefore close to the final printing, it is possible to present it in box form.

-

- 5. Prototyping

- With our prototyping line, we are able to create satisfactory samples of new product packages required by customers rapidly for meetings, negotiations, etc. In response to customers' requirements, we can promptly and flexibly handle everything from new product development and design to plate-making and correction.

Toin Corporation

Toin Corporation